Buttweld Fittings

A pipe fittings is defined as a part, used in piping system to change direction or function, which is mechanically joined to the system. Probably the simplest way to achieve this end would be to bend the pipe in the direction required, but this process will stretch and thin the outer wall whilst thickening and wrinkling the inner wall. This results in flow resistance and accelerated wall erosion.

A second method sometimes used is a mitred joint. Where pipe are cut to the correct angle and welded together to achieve the desired change. Whist the cross-section area and wall thickness are maintained a great deal of efficiency is lost due to friction and turbulence resulting from the severe changes is direction; for example a single-mitred bend offers about six times the resistance of a swept elbow.

For these reasons swept fittings are preferred on most piping systems, particularly where internal pressure, flow and corrosion are major considerations.

Stainless Steel: ASTM A 403

Grade: WPS/WPW 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H

Carbon Steel: ASTM A 234

Grade:. WPB/WPBW, (IBR/Non IBR)

Alloy Steel: ASTM A 234, Gr. WP1, WP11, WP22, WP5, WP9, WP91, (IBR/Non IBR)

Nickel Alloys:

Grade:

Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201),

Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500),

Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825),

Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625),

Inconel 601 (UNS No. N06601),

Hastelloy C 276 (UNS No. N10276),

Alloy 20 (UNS No. N08020),

Titanium (Grade I & II)

Duplex Steel

Grade: 2205 (UNS No. S31803), 2207 (UNS No. S32760)

Copper Alloys:

Aluminium, Copper, Brass & Gunmetal

UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500

UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Types : Elbow, Tee, Reducer, Return Bends, Stub-Ends, Cap, Colla, Cross, Insert, etc.

Size : 1/8"NB TO 48"NB. (seamless & welded)

Wall thickness : sch. 5s to sch.xxs

| |

|

|

|

| ELBOW 90oLR |

ELBOW 90oSR |

ELBOW 45oLR |

| |

|

|

| MATERIAL

: |

304/304L ,

316/316L |

| THICKNESS: |

SCH10S , SCH 40S |

| SIZE

: |

90o LR 1/2"~24" |

| 90o SR 1"~6" |

| 45o LR 1/2"~24" |

|

| |

|

|

|

|

|

| EQUAL-TEE |

RED-TEE |

|

| |

|

|

| MATERIAL

: |

304/304L ,

316/316L |

| THICKNESS: |

SCH10S , SCH 40S |

| SIZE

: |

Equal Tee 1/2"~12" |

| Reducing Tee 3/4"x1/2"~12"x8" |

|

|

| |

|

|

|

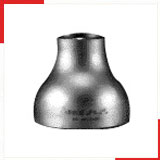

| CON-RED |

ECC-RED |

ECC-RED |

| |

| MATERIAL

: |

304/304L ,

316/316L |

| THICKNESS: |

SCH10S , SCH 40S |

| SIZE

: |

CONCENTRIC REDUCER 3/4"x1/2"~12"x8" |

| ECCENTRIC REDUCER 3/4"x1/2"~12"x8" |

|

|

| |

|

|

|

| |

CAP |

|

| MATERIAL

: |

304/304L ,

316/316L |

| THICKNESS: |

SCH10S , SCH 40S |

| SIZE

: |

1/2"~12" |

|

|